MS140 how does it work?

The simplicity of the MS140

“How does it work?”

*Introduction

When a complete new product is launched it is important for potential customers to understand what they buy.

Our light weight machine MS140 is completely new in many ways so we want to explain the functions and features of the machine.

An important rule for technical products is: “The simpler the better”.

How does it work / the principles.

* The constant pull tensioner.

The principle of the MS140 tensioner is very simple and exactly the same as that of the MS200, that we produce since 1992:

-When the lever is lifted the spring is ”loaded with force” and the string is tensioned by this force after clamping the string in the tension head.

-The tension head is always locked in the starting position and this lock releases automatically when a string is clamped.

This pictures shows the complete drive system of the MS140

*The constant pull action is perfect and without overshoot.

Because the spring system will always want to be in balance with the tension in the string, every small loss of tension will be compensated by the tensioner, resulting in a perfect constant pull action. A spring tensioner can not overshoot the tension like many electronic machines do.

This graph shows how accurate a spring can keep the tension constant.

For comparison the graph of a good quality electrical machine

*A spring is a very reliable and durable “drive system”.

It is very important that the springs do not loose force during their long life. Therefore the springs are “overdimensioned” for the force that they have to supply. This same principle was used in the footoperated MS200 and there are still machines in use built in 1992 without changing the springs.

*Easy calibration.

It is very easy for the stringer to calibrate the tensioner with the caliabration screw to obtain maximum accuracy. A calibrator is supplied with the machine.

*The racquet mounting with direct racquet support.

The stiffness of the turntable.

The main task of the racquet support is to prevent the racquet from getting shorter under the load of the tensioned main strings.

Compared to other turntables the principles of the MS140 cradle are quite different:

– With most cradles the “towers” are clamped on the main beam and the friction has to prevent the supports from moving inwards.

The forces of the main strings cause a bending load on the main beam, which will bend the beam under this load.

-On the MS140 cradle the forces of the main strings are transfered to the screw spindle by the guiding arms.

This results in a pressing force in the spindle and pulling force in the frame of the cradle. Parts are much stronger against pulling and pressing forces than against bending forces.

This is why this cradle is very stiff and much lighter.

-The screw spindle also makes it possible to adjust the racquet support very accurately at the size of the racquet head.

*The racquet support.

Stringing machines have either direct or indirect racquet supports. Direct supports work against the inside of the frame directly against the forces of the main strings preventinng the racquet from getting shorter.

Indirect supports work against the outside of the racquet preventing it from getting wider.

The MS140LS has a 5 point direct racquet support

This document shows “famous” machines with the direct supports

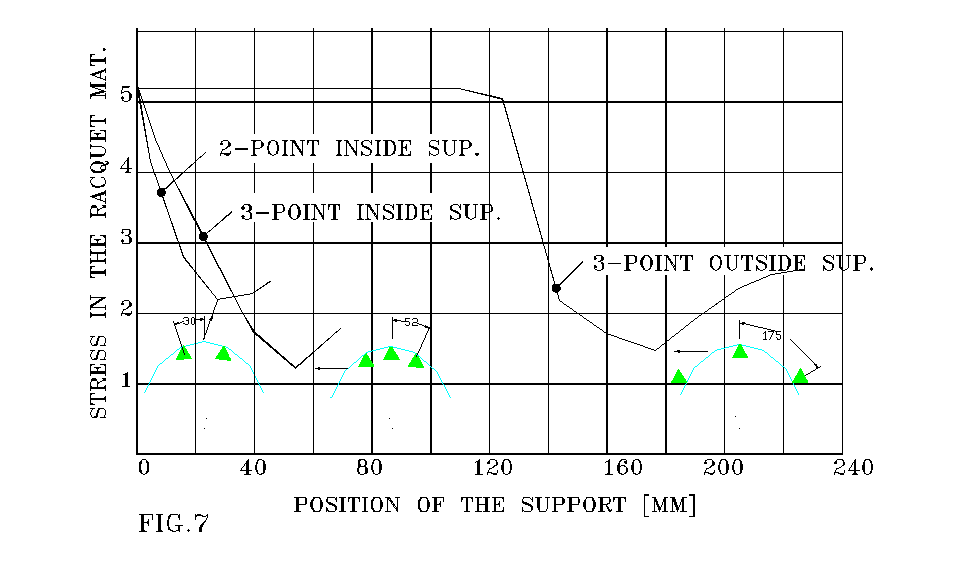

This graph shows the stress in the racquet material with different types of racquet supports. It shows that very simple 2 point inside supports offer a very good support and that with an outside (indirect) support the stress in the racquet depends strongly on the position of the supports.

*The clamps.

The MS140’s are supplied with Stringway flying clamps which are quite famous and are sold in large quantities to owners of other stringing machines.

The quality of the clamps decide about the accuracy of the string job. Important qualities are to prevent the string from sliding and to minimize the movement of the clamp at the moment that the tension is taken over from the tensioner (drawback).

The general opinion about flying clamps is that they lose more tension than fixed clamps, which is probably true for double flying clamps.

But this is certainly not true for our triple flying clamp for 2 reasons:

– The triple clamp clamps 3 mains at the same time so the drawback is smaller than with the double clamp.

– Compared to fixed clamp systems there is no “leak way” for the tension leaking a way to the guiding system.

The MS140’s are available with triple or double flying clamps.

-This picture shows how the clamps are used in different situations.